In the realm of chemical engineering, especially in separation processes like 蒸留, 吸収, そして stripping, the column’s internals play a crucial role in influencing operational efficiency. One of the key internals is column packing, which provides a contact surface for two phases (gas and liquid), facilitating mass transfer.

Packing is a material placed inside columns to enhance the contact between gases and liquids during processes such as distillation, 吸収, and stripping. It offers a large surface area for the interaction of the two phases, improving mass transfer and separation efficiency.

There are two main types of packing: random packing そして structured packing. Each type has its own design, advantages, and optimal applications. Selecting the appropriate packing is vital as it can impact the column’s performance, energy consumption, and overall process cost.

There are two primary types of packings:

- ランダム梱包

- 構造化された梱包

Let’s examine the differences between the two and understand why structured packing is the preferred choice when high surface area and excellent performance are required.

ランダム梱包

Random packing consists of loose pieces, such as Raschig rings, Berl saddles, Pall rings, and other shapes, that are dumped into the column to fill a specific volume. They arrange themselves randomly, creating a winding path for fluids to flow and interact.

- Characteristics of Random Packing:

- Simple installation: No specific orientation or arrangement required.

- Cost – effective: Generally less expensivein terms of both material and installation.

- Moderate surface area: Offersa reasonable area for mass transfer, but not optimized.

- More proneto maldistribution: Fluid paths may be uneven.

- Higher pressure drop: Due to the irregular arrangement and possible

Random packing is suitable for small to medium – sized columns and for operations where moderate efficiency そして lower capital investment are acceptable.

構造化された梱包: Where Design Meets Performance

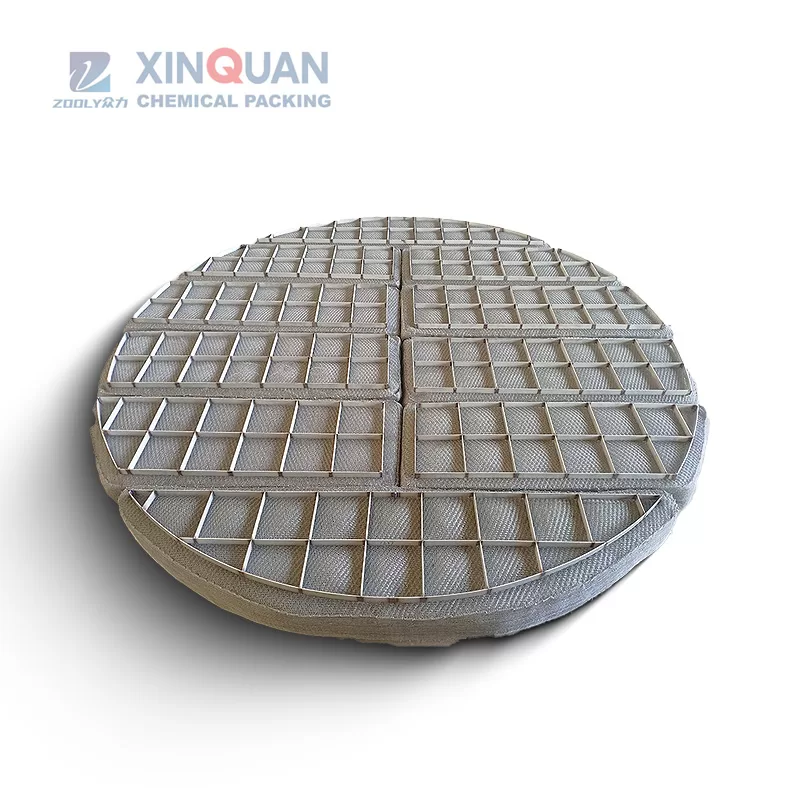

Structured packing is a geometrically arranged packing consisting of corrugated sheets, usually 金属, ceramic, or plastic, stacked in a precise orientation. These sheets are arranged to guide fluid flow along specific, predictable paths, promoting uniform liquid distribution and maximizing phase contact.

Why Structured Packing Excels?

- High Surface Area

The structured geometry creates significantly more surface area than random packing, ensuring more efficient contact between the gas and liquid phases. This results in faster and more complete mass transfer.

- Low Pressure Drop

Because of the open, well – organized channels, structured packing allows smooth and uninterrupted vapor flow. This is particularly advantageous in vacuum distillation, where pressure drop needs to be minimized.

Superior Efficiency

The uniformity of flow paths ensures that every part of the packing is utilized, reducing dead zones and enhancing overall column performance. High HETP (Height Equivalent to a Theoretical Plate) values make it ideal for precision separations.

- Scalability and Predictability

Since the structure is regular, the performance can be modeled and scaled up more reliably than with random packing, which may behave unpredictably at larger scales.

- Reduced Fouling

Well – channeled flow paths reduce the risk of fouling, especially when compared to the more chaotic paths of random packing.

Comparison Table: Random vs. 構造化された梱包

Where Structured Packing Shines the Most

Structured packing is often used in:

- Cryogenic air separation

- Vacuum distillation in refineries

- Pharmaceutical or fine chemical industries where high purity is critical

- Carbon capture and absorption systems with stringentefficiency requirements

- Revamping old towers to improve performance without increasing column diameter

In such systems, the combination of 低い圧力損失, enhanced efficiency, そして high throughput justifies the higher initial investment.

Conclusion: Efficiency with Structure

Both random and structured packings have their roles in process engineering, and choosing the right one depends on the application, budget, and performance objectives.

But when your process demands maximum mass transfer efficiency, low pressure loss, high product purity, そして scalable, predictable performance, then structured packing surpasses random packing.

It may cost more initially, but it delivers where it matters most—in the performance of the column and the quality of desired separation.

平祥新泉化学包装有限公司, Ltd.

平祥新泉化学包装有限公司, Ltd.